- Information for Teachers

Toward the realization of a recycling society where goods and energy circulate

2021.09.01

Countries around the world are moving toward a carbon-neutral society in which CO₂ emissions are controlled and the emission balance is zero. In order to achieve this, it is important to drastically change the recycling system for plastics, which are now a material that supports society. How can we create a system that reduces new inputs of carbon resources and maximizes the recycling of available resources?

assistance in news gathering

EBARA Corporation

Environmental Business Company

General Manager, Business Planning Dept.

Indian bead tree (Melia azedarach)mythical founder of Koreacure(Mr. Keiji Senzan

Ebara Environmental Plant Co.

Development Department, Common Infrastructure Division

Manager, New Technology Development Section

Takayuki Ihara(Mr. Takayuki Ihara

Recycling technologies needed to achieve carbon neutrality

Carbon neutral means CO2emissions and absorption minus zero. Currently, the combustion of fuels and wastes results in CO2emissions exceed the amount absorbed by forests and algae. Therefore, it is necessary to reduce fuel use by expanding the use of renewable energy, to reduce waste by changing product materials and new recycling technologies, and to create a system that maximizes the recycling of available resources.

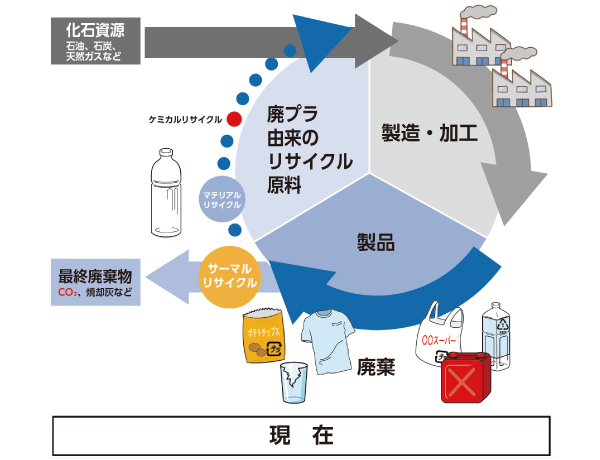

According to data from 2019, approximately 8.5 million tons of plastic was disposed of in Japan, of which 64% was combusted, including thermal recycling, which recovers the heat energy from the combustion process and utilizes it. Material recycling, in which plastics are crushed, sorted, cleaned, and turned into raw materials for products again, accounts for 22%. Chemical recycling, in which plastics are broken down into smaller molecules and reused as raw materials in the chemical industry, accounts for only 3%.

emissions from waste disposal2 In order to reduce emissions of waste plastics and recycle waste plastics as resources, it is necessary to increase the ratio of the latter two, but there are still many issues to be addressed. For example, material recycling is currently limited in the types of materials that can be recycled, and the quality of materials deteriorates if they remain dirty or are mixed with other types of materials. For this reason, a high percentage of PET bottles, which are easily identified as a single material, are being recycled, but it is difficult to clean and separate materials such as packaging materials for food and daily necessities, and the more new materials such as biomass-derived plastics are added in the future, the more difficult it will become to separate them correctly. The more new materials such as biomass-derived plastics increase in the future, the more difficult it will become to separate them correctly. Chemical recycling, which can process even dirty or mixed materials, is expected to be the answer to this problem.

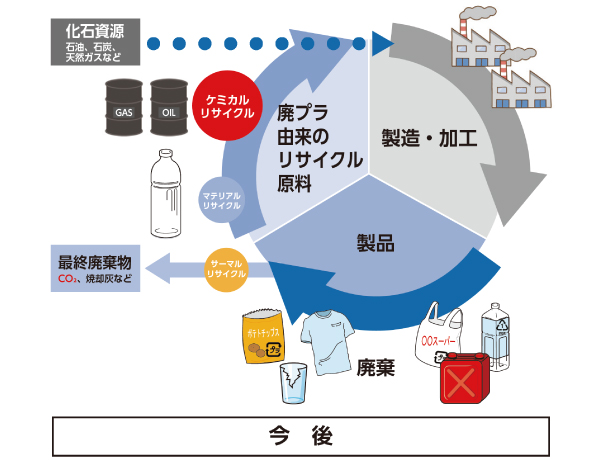

CO2Reduce waste by 80% and recycle resources

Chemical recycling is a technology that decomposes waste materials at high heat to extract hydrogen, carbon monoxide, ethylene, propylene, and other substances. For example, the ICFG® Internal Circulating Fluidized Bed Gasification System developed by Ebara Environmental Plant Corporation consists of a furnace divided into two chambers: a pyrolysis chamber and a media regeneration chamber. In the pyrolysis chamber, the input waste is decomposed by high heat and chemical feedstock gases are extracted. Residues that are not fully decomposed in the pyrolysis chamber are sent to the other media regeneration chamber and burned, and the combustion heat is used for pyrolysis in the pyrolysis chamber.

Normally, burning 1 ton of plastic emits 3 tons of CO₂, but chemical recycling can reduce emissions by about 80% by extracting carbon resources in the form of gas or oil whenever possible. However, the cost was higher than simply burning waste plastic, and at that time, there was not as much social need for this technology as there is today, so it did not become widely used. Compared to those days, nowadays, efforts to reduce environmental impact are directly related to corporate value, and the need to introduce chemical recycling technology into society is increasing.

However, there are challenges in utilizing ICFG.®In the case of the "waste plastics" facility, the carbon resources that can be extracted are also diverse because the facility can accept a wide variety of waste materials such as municipal solid waste and biomass, in addition to waste plastics. Since the extracted materials vary depending on the pyrolysis conditions, it is necessary to design the facility in cooperation with chemical manufacturers that use the materials, taking into consideration how the materials will be used. Since there are no facilities in actual operation yet, it is difficult for people to understand the value of this technology. We would like to make this technology known to society by first creating a medium-scale facility and making it visible to many people," said Keiji Genjidan of EBARA Corporation.

More options for your ideal future

Six years after the SDGs were announced at the UN Summit in September 2015, individuals and companies are becoming more environmentally conscious, but what form of society is truly sustainable? A society in which waste can be sorted by material, cleaned, transported, and recycled may seem ideal, but each of these processes requires energy and constant effort on the part of people to cleanly sort waste. ICFG, which can collectively recycle a wide variety of wastes®Chemical recycling using the "Gyodan" can be said to be a technology that realizes a slightly looser recycling process," says Mr. Genjidan.

We still do not know what kind of balance between material recycling, chemical recycling, and thermal recycling is optimal. That is why it is necessary to realize new recycling technologies and to develop, demonstrate, and disseminate product manufacturing technologies that utilize raw materials recycled from these technologies and biomass-derived materials, thereby increasing the number of options available to us. And we should not be content with simply sorting the garbage in front of us, but rather investigate how it is disposed of beyond that point and consider how to make it better than it is now, which will lead to the realization of a sustainable society.

'TheEducational Support vol.51From "The